REAL-TIME FORKLIFT TRACKING AND LOGISTIC MANAGEMENT

Improve equipment usage and productivity, and reduce accidents with an innovative forklift tracking system

Purchase, leasing, and operation of forklifts are expensive investments for manufacturing companies. In addition, they can get involved in accidents that create a big safety risk to your business. As a consequence, getting the precise location of forklifts becomes essential. Logistics is moving toward automatic processes and integrated technology, to improve the operations and the forklift fleet management. For this reason, thousands of logistics companies are integrating advanced tracking systems. Dragonfly can help you track your forklifts with a precision of up to 10 centimeters. Dragonfly does not require the deployment of a dedicated infrastructure like UWB antennas or anchors, BLE or WiFi receivers, RFID tags, etc. For this reason, it is considered the best and most flexible indoor tracking technology available on the market today.

Download the full case study now and discover more about how Dragonfly is improving the operations at Florim!

THE PROBLEMS: IMPROVING OPERATIONS AND ELIMINATING ACCIDENTS AND COLLISIONS

Forklifts expedite countless industrial processes however...

Forklifts are involved in nearly 100,000 injuries per year in the U.S. alone

..and this number does not even account for other costly accidents, such as instances where forklifts damage assets like pallets of products, industrial machinery, the warehouse structures or other vehicles.

It is common for forklifts to go missing on large sites

This can create huge delays in task completion, even when other forklifts are available. As a consequence, operational costs go up and reduce the competitiveness of your company.

It's expensive to store and maintain forklifts to regulatory standards

While some are constantly in-use, many other forklifts might go unused (or under utilized) for long periods of time, and it is then challenging to predict when maintenance work needs to be done.

As a result, all these issues translate into high costs in time and waste of money. Similarly, site managers can drive high returns by knowing just a few simple pieces of data such as:

- Where each forklift is;

- Where it has been;

- How long it spends in each location;

- etc…

THE SOLUTION: DRAGONFLY FOR WISE ASSET TRACKING, AND MICRO-LOCATION SYSTEM OF FORKLIFT TRACKING

Our forklift tracker software uses a computer vision technology to elaborate the real time location of forklifts with a precision of 10 centimeters.

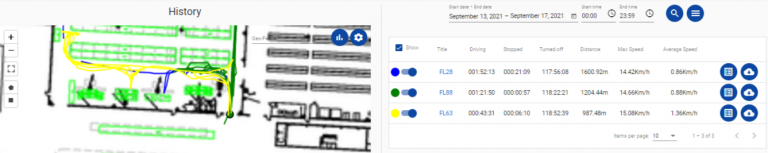

Real-time and historical positions inside the Dragonfly Cloud Dashboard

Warehouses managers can download and analyze this data to monitor vehicle usage over time by different operators. It is possible to gather information about work productivity, vehicle efficiency and which forklifts are being underutilized. As a result, you can reduce your operational costs and improve the overall management.

Real-time positions and historical locations via API and CSV files

The forklift tracking system is ideal for warehouses, industrial facilities, loading docks, and construction sites. Software developers can integrate the location data into their existing WMS and create a complete forklift tracking and safety solution. In addition, custom applications can be developed. For instance, Dragonfly can be used to perform automated picking inside the warehouse.

THE RESULTS: BETTER ROUTES, OPTIMIZED OPERATIONS, SAFER WORK CONDITIONS AND REDUCED DOWNTIME. AS A RESULT, LOWER COSTS AND HIGHER ROI

Historical and real time location

By tracking forklifts, logistics managers are gaining full real-time visibility of the fleet. They can not only know the exact location of each forklift in real-time, but also have the ability to track their historical locations with pinpoint accuracy.

Optimize operations and reduce losses of time

Looking for inactive vehicles, better utilization-planning in the warehouse by knowing each item's exact location, and seeing who is doing which task in real-time, help achieve higher utilization. This means a great reduction in costs.

Route optimization

Route optimization is possible by analyzing the historical paths of the units. The location data provided by Dragonfly can be used for analysis and improvements of the operations. As a result, you will reduce the time needed to perform tasks and reduce the risk of accidents. Remember this equation:

Less distance traveled = Less probability of collision

Reduce costs

Speaking of cost, a large warehouse can have up to a dozen or more forklifts and similar vehicles in operation at a time. This big fleet means a big impact on your budget. Businesses have money invested in the purchase or leasing of vehicles, maintenance, electricity for recharging, and the expense of extra workers to operate those vehicles. For these reasons, warehouse optimization becomes essential to reduce the operational costs.

With Dragonfly you can potentially reduce the size of your fleet. There are three main ways this happens:

- Increasing forklift utilization

- Optimizing forklift capacity

- Optimizing forklift routes

As a result, you can reduce the operational costs of your warehouse and improve the supply chain management. In conclusion, Dragonfly is a key component for modern and innovative fleet management systems. Logistics operators are implementing advanced technologies to stay one step ahead of competitors by improving their warehouse operations with the help of solutions that create “smart warehouses”.

REAL DATA TO OPTIMIZE THE WAREHOUSE OPERATIONS

Remember the famous quote “if you can’t measure it you can’t improve it”? Using Dragonfly tracking data can be analyzed and used by management to define warehouse rules and forklift routes. It can be helpful to understand if operators take too much time to get the items in the warehouse, or even how many breaks an operator takes and how long. As a result, you can understand how your operators work. Dragonfly gives you complete access to these data:

- Real time location as metric coordinates (X, Y)

- Real time location as WGS-84 coordinates (latitude and longitude)

- Orientation (pitch, yaw, roll)

- Maximum and average speed

- Time in movement, time stopped, time offline

In addition, Dragonfly allows you to see the routes of each forklift thanks to the Dragonfly Cloud Dashboard. An advanced visualization can bring additional insights, and an understanding of processes to streamline the traffic and remove bottlenecks. Heatmaps can show the density of the traffic within the facility, and spaghetti diagrams can visualize the continuous flow of traffic throughout the halls. These commonly understandable visualization methods help improve the operations, and therefore let you cut costs of projects, and the general cost of operations.

DRAGONFLY CLOUD DASHBOARD

Track the real time and historical locations of your devices

Add a floor plan to see the location on a real blueprint

Visualize your data as: spaghetti lines, time lines, height lines and heatmaps!

Search data for 1 day or across multiple days

Search for data related to a specific area (geo-fence)

Get metrics like: maximum and average speed, travelled distance, drive time, stop time etc..

Export your data as plots and CSV files

WHAT ARE THE SYSTEM COMPONENTS?

The (recommended) on board processing architecture is composed of:

- A USB wide angle camera

- A powerful compact mini-PC

The camera has to be mounted on the roof of the vehicle and pointed towards the ceiling. The computing unit is usually placed inside a junction box behind the driver’s seat. Onit can provide the camera pre-calibrated, and the computing unit already pre-configured with the Dragonfly Kits. Contact us now to get more information!