Florim Ceramics uses Onit’s Dragonfly system to track forklifts indoors and outdoors, improving visibility, efficiency, and safety.

THE CLIENT

With an innate passion for beauty and design, Florim has been producing ceramic surfaces for every building, architecture and interior design needs for over 60 years. Headed by Claudio Lucchese, the company has a past rooted in the Italian ceramic district and a present as an international trendsetter in the industry. It has more than 1,500 employees worldwide and a turnover of more than 584 million euros by 2022.

Florim Ceramiche is a company committed to technological innovation, with a particular vocation as an "early adopter": in fact, it is often at the forefront of testing innovations on the market, such as indoor and outdoor localization technology, in order to benefit from their advantages and optimize logistics inside and outside the warehouse.

CUSTOMER NEED

Florim Ceramiche had previously invested in cutting-edge solutions to enhance warehouse management. Ten years ago, the company first explored the use of localization technologies and implemented Forklift Guidance System software to address the specific warehousing needs of its various plants.

However, as the reliability of the system no longer met the company's standards, and due to a lack of support from the original supplier, Florim Ceramiche wanted to implement an advanced technological solution that could provide precise X, Y, and Z coordinates of the forklifts with centimeter-level accuracy.

THE SOLUTION

Based on the identified needs, Onit introduced the innovative Dragonfly solution to Florim Ceramiche.

In the initial design phase, to manage costs and validate the technology, Florim Ceramiche and Onit agreed to run a Proof of Concept (PoC). This involved outfitting two forklifts with the necessary cameras and sensors. During the testing phase, the outdoor localization immediately proved to be highly accurate and far more reliable than the previous system.

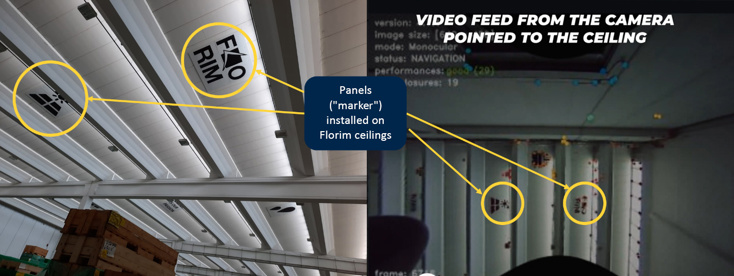

However, a special approach was required for the indoor localization: the goal was to take advantage of the distinctive features of the Florim Ceramiche warehouse ceiling to track the moving assets inside the facility.

However, it quickly became apparent that the insufficient lighting in the warehouse was hindering the quality of image processing. To address this challenge, Onit implemented a clever solution: placing markers in key areas of the ceiling to help Dragonfly function effectively in low-light conditions and on ceilings with limited distinguishing characteristics.

ACHIEVEMENTS

The Proof of Concept (PoC) at the Fiorano plant was successfully validated, which led to the expansion of the project to the Mordano plant. In total, around 80 forklifts are now outfitted with Dragonfly technologies.

Today, Florim Ceramiche benefits from a new system that provides more precise and real-time tracking of forklifts both indoors and outdoors, far surpassing the accuracy of their previous solution.

Moreover, the Forklift Guidance System software now includes Auto-ID functionality, which enables pallets to self-identify during storage and retrieval without the need for a barcode scanner.

These improvements have brought several key benefits, including:

22% improvement in forklift operator efficiency

Reduced errors in item storage and retrieval

Better real-time visibility of forklift fleet activities in the control room

Enhanced safety for pedestrians in the warehouse